Fuel cells vs. batteries: choosing the best solution for modern warehousing

In a world where logistics efficiency can mean the difference between staying competitive or falling behind, with more than $7.4 trillion in global online sales expected by 2026 and over 2.77 billion digital buyers, warehouses have become strategic hubs of present and future commerce. From order picking to last-mile delivery, every process matters. But there’s one silent factor that conditions the performance of this entire chain: the energy source powering these warehouses, especially when comparing fuel cells vs batteries

Choosing how to power a logistics fleet is no longer just a technical decision. It’s a high-impact operational one. It affects productivity, equipment availability, maintenance costs, space usage, and even the facility’s environmental footprint. And that leads us to the big question: Should warehouses continue relying on lithium-ion batteries, or has hydrogen’s time come?

In this article, we’ll break down the advantages and limitations of both technologies, explore their logistical and environmental implications, and explain why hydrogen is gaining traction as a scalable, clean, and efficient energy solution for today’s warehousing needs.

Lithium battery forklifts: benefits, limitations, and hidden costs

For years, lithium-ion battery-powered forklifts have been the preferred choice for logistics operations seeking a cleaner alternative to diesel. And with good reason: batteries offer local zero emissions, lower mechanical maintenance, and quieter operation.

However, behind these advantages lie several limitations that have a direct impact on productivity and total cost of ownership. One of the most critical is recharge time, which can extend for several hours, rendering the vehicle inactive. This requires spare batteries, dedicated charging areas, and tight operational planning to avoid downtime.

In addition, battery performance tends to degrade over the course of a shift, especially under high demand or extreme temperatures, which affects operator efficiency. On top of this, the battery’s lifespan deteriorates with each charging cycle, reducing its capacity over time and requiring replacement every few years, a cost often underestimated at the planning stage.

Another often-overlooked issue is the space required for charging zones, which not only consumes valuable warehouse floor space but also creates safety risks and entails additional infrastructure and ventilation costs. While lithium batteries remain a useful solution in many scenarios, their operational and structural limitations become increasingly evident in contexts that demand resource optimization, extended shifts, and environmental accountability.

Hydrogen forklifts: advantages for logistics

Hydrogen-powered forklifts are emerging as a real and competitive alternative to batteries, particularly in logistics environments that require continuous availability, agility, and energy efficiency.

One of their main advantages is refueling time: while a battery takes hours to recharge, a hydrogen forklift can be refueled in just 2 to 3 minutes. This eliminates the downtime associated with battery swaps or charging and gets the vehicle back in operation almost immediately. In multi-shift operations, this difference translates directly into increased productivity.

Another key benefit is consistent power throughout the shift. Unlike batteries that lose performance as they discharge, hydrogen fuel cells deliver steady energy output until the tank is empty, ensuring a more efficient and consistent user experience.

From an environmental perspective, hydrogen forklifts produce zero local emissions and have a minimal carbon footprint when green hydrogen is used. They also reduce reliance on lithium and eliminate the need for other critical materials with significant environmental impacts, such as nickel and cobalt.

In terms of infrastructure, modular systems like Hydros Power’s interchangeable hydrogen capsules enable scalable solutions without the need for complex refueling stations. This makes adoption easier and lowers initial implementation costs.

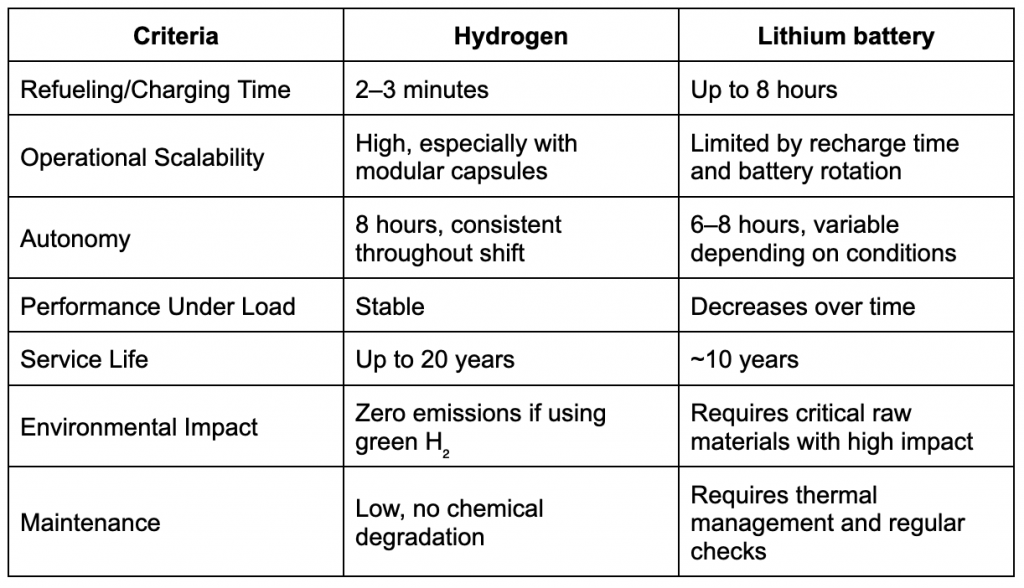

Hydrogen vs. Lithium: key comparison table

To make the comparison between both technologies easier to understand, we present a clear breakdown between lithium battery-powered forklifts and those powered by hydrogen fuel cells. This table highlights the key differences across technical, operational, economic, and environmental aspects.

This comparison shows that, while batteries may be suitable for smaller or less demanding operations, hydrogen fuel cells offer a significant advantage in high-rotation environments, 24/7 operations, and settings where space and efficiency are critical factors.

The choice between lithium batteries and hydrogen fuel cells is no longer just technical. It’s strategic. It directly impacts the efficiency, sustainability, and competitiveness of any modern warehouse.

In this first article, we’ve explored the technical characteristics, advantages, and limitations of both technologies in the context of fuel cells vs batteries. The comparison makes it clear that, while batteries remain valid in certain scenarios, hydrogen stands out as a robust, scalable solution capable of meeting the demands of today’s logistics.

Want to know if hydrogen is a good fit for your warehouse?

We’ll help you analyze your operations and design the solution that best fits your needs. We believe that the shift toward cleaner logistics starts with concrete decisions, and we’re here to help you take that first step.